50 CIP Washing system with resistance heater - 2 Tanks

Description

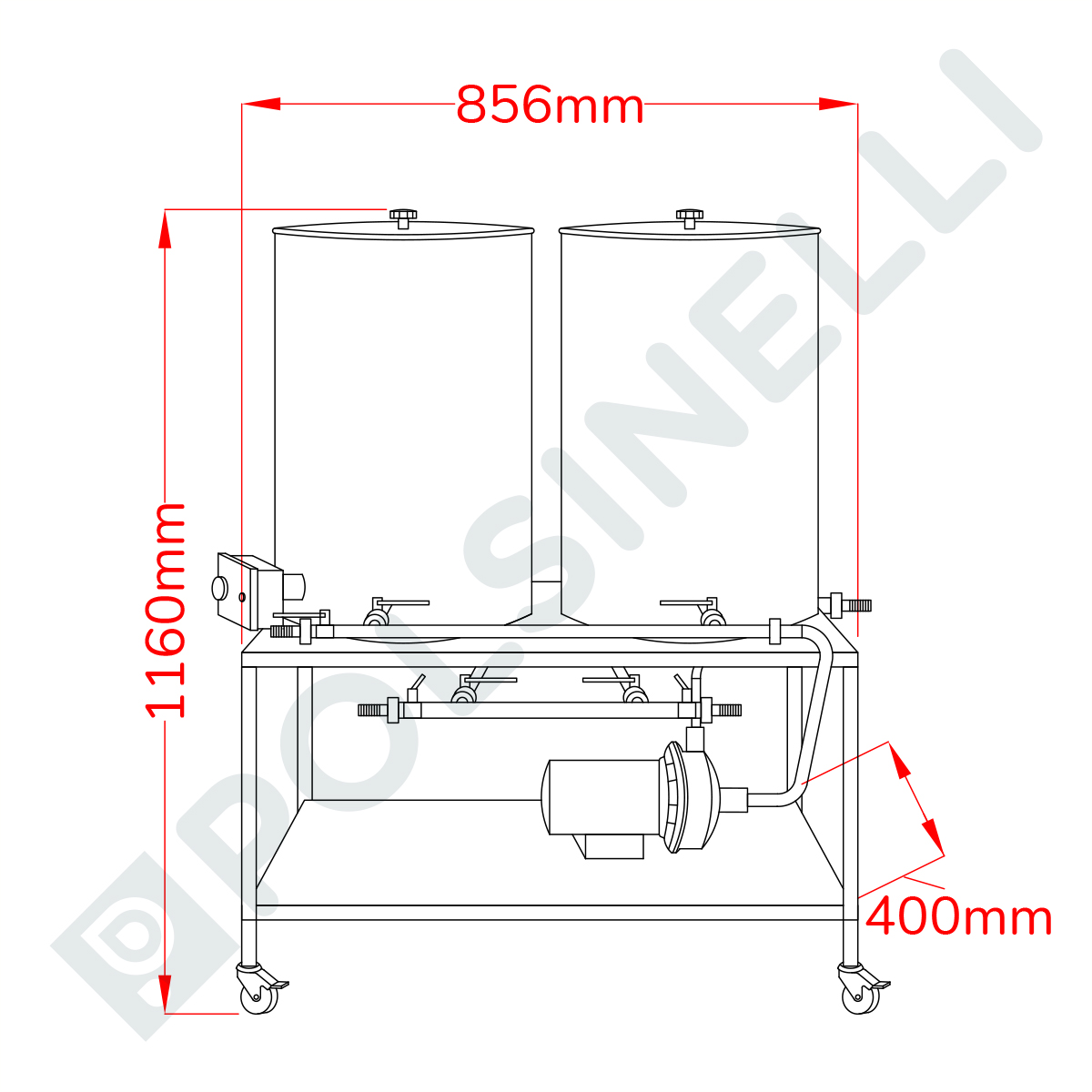

CIP washing system 50 with resistance - 2 Tanks

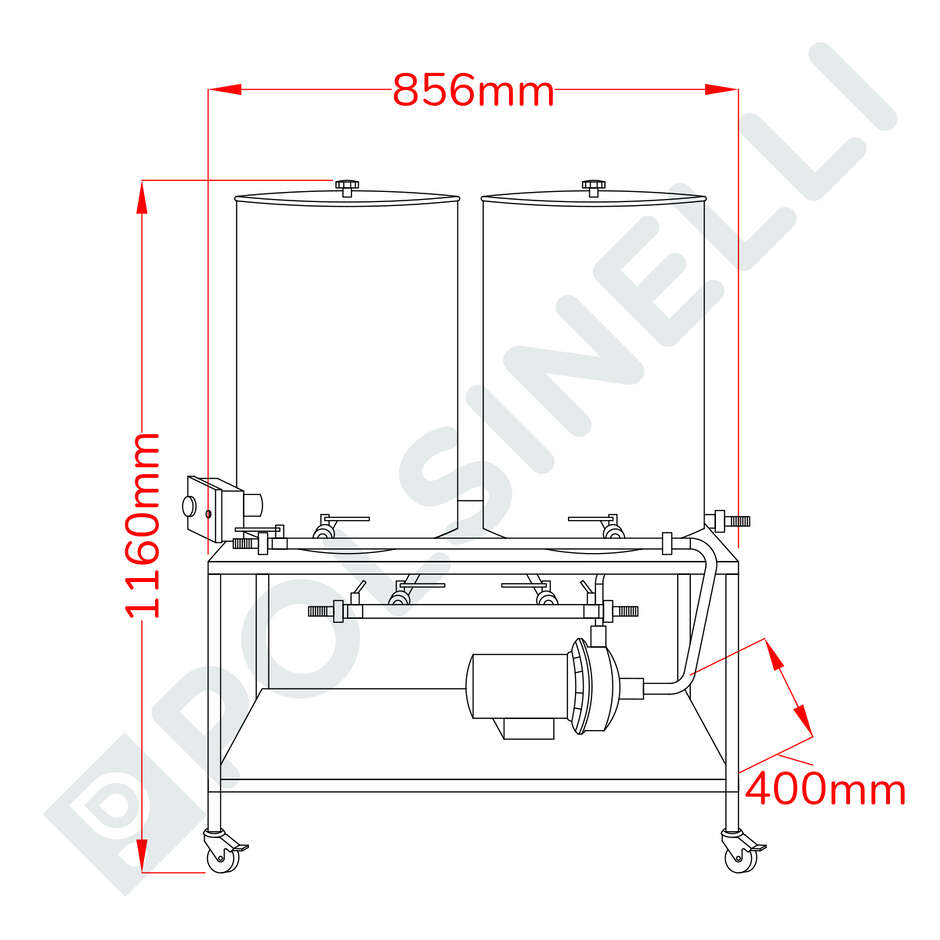

Clean In Place is an automatic cleaning system, which must be accompanied by the cleaning system, which makes a recycling, at certain pressure and/or temperatures, of cleaning liquids and solutions for rinsing. Completely made of stainless steel 18/10 for food on a wheeled chassis to facilitate its movement. With this system, we ensure that the cooking system and fermenters are cleaned by organic and inorganic contaminants. It is composed from nr. 2 50 lt. tanks, but on request we can build the installation with variable capacity tanks, from 100 liters to 200 liters, complete with variable power pumps.

The CIP washing system (Clean-in-place) allows the cleaning of the internal surfaces of pipes, tanks, equipment, filters and related connections without any need for dismantling. Furthermore, the trolley envelope allows maximum mobility of the whole structure.

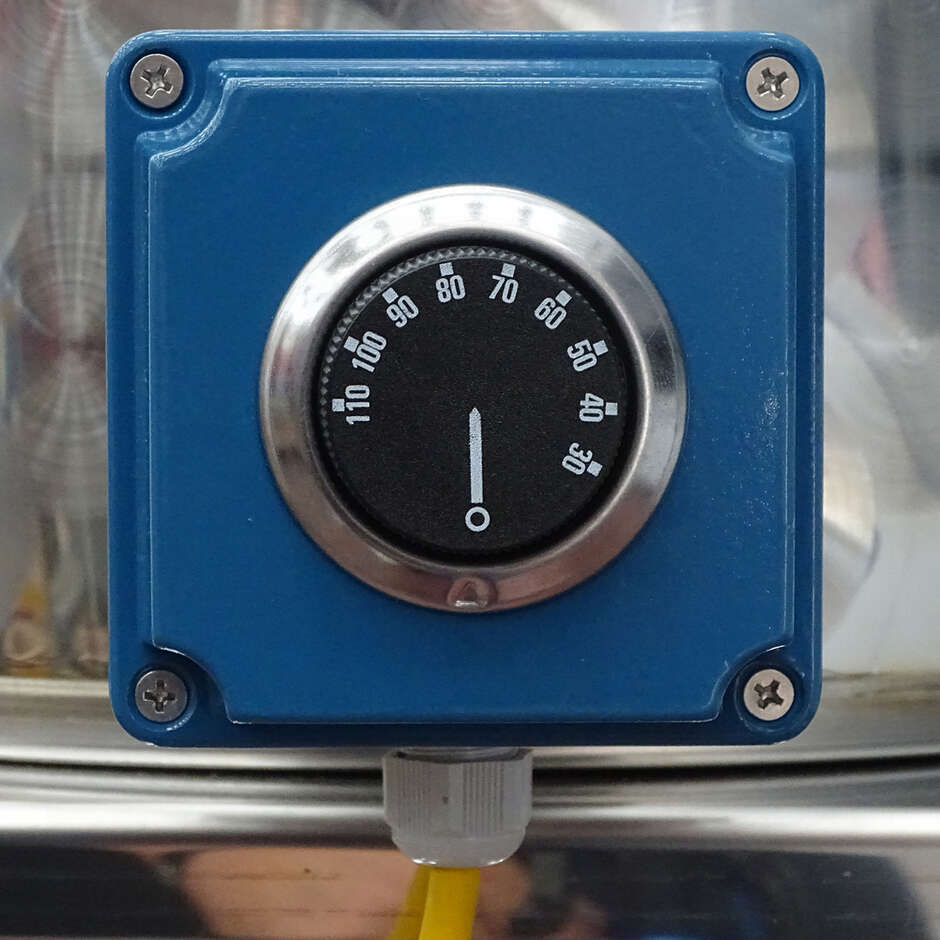

This system is equipped with an electrical resistance with whom it is possible to manage the water temperature in the tank containing the alkaline solution. This allows to improve the cleaning process efficiency.

Usually it is used with:

- Alkaline solution, descaler;

- Sanitizing solution with peracetic acid;

- Water or other

Thanks to the washing CIP system it will have a significant saving of soap, soda, acid and other things, because once the solution is sent from the first tank to the fermenter to be cleaned, the valves of the tank can be closed and the recycling plant can be used. The "recovery" tube will be linked by the end of descaler and the solution will be recovered, if necessary, for a new use.

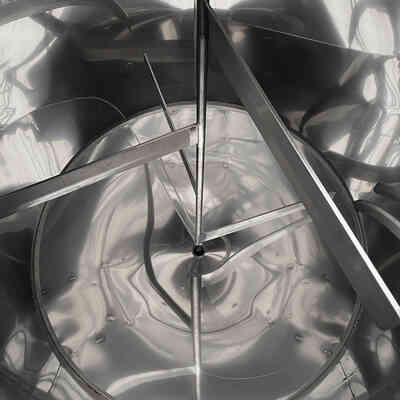

The tanks shall be equipped with a valve at the bottom and a front one 40 mm from the bottom, the solution shall be recharged from the bottom and caught frontally to avoid recycling any residues.

For systems up to Junior 300 extra

Features:

- DIN 15 stainless steel valves

- Connections: DIN 15 F

- Fittings spanner DIN 15-32

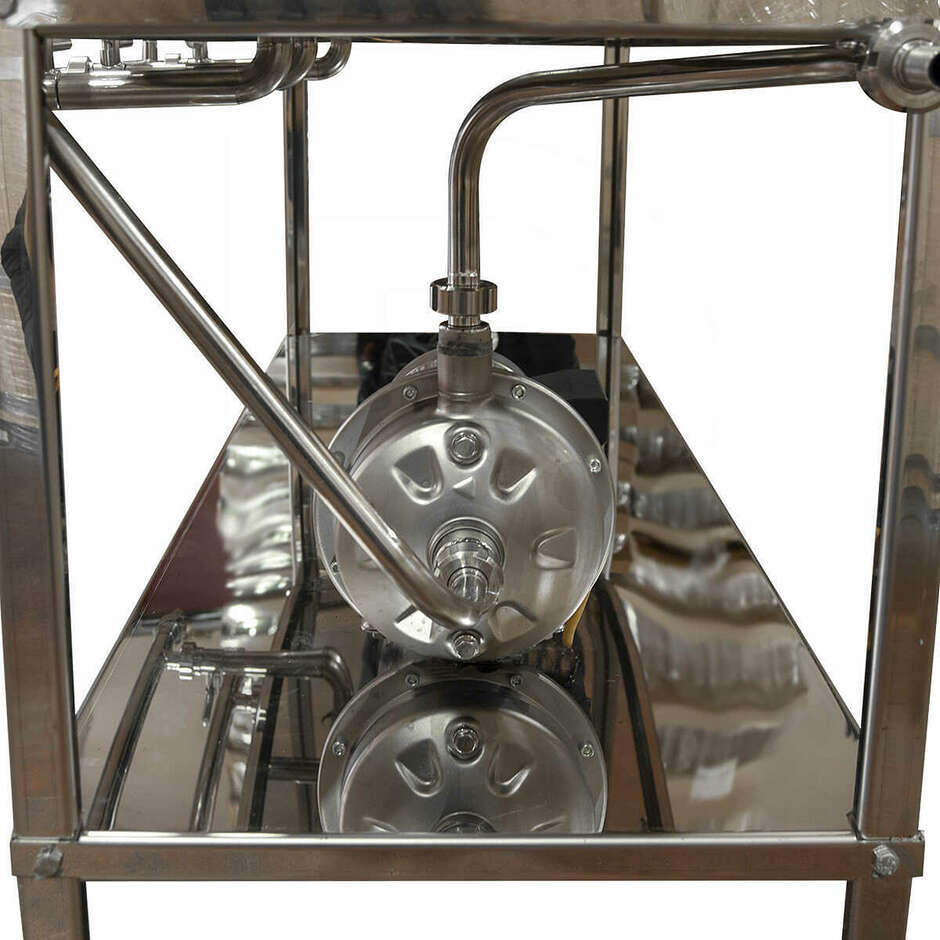

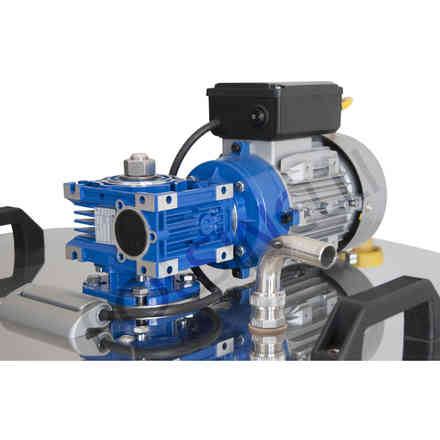

- Stainless steel electrical pump: 0,75 kW; flow rate 110 L/m; HP 1; T/max 110°.

- With trolley

- Dimensions: mm 1100x580x1150h

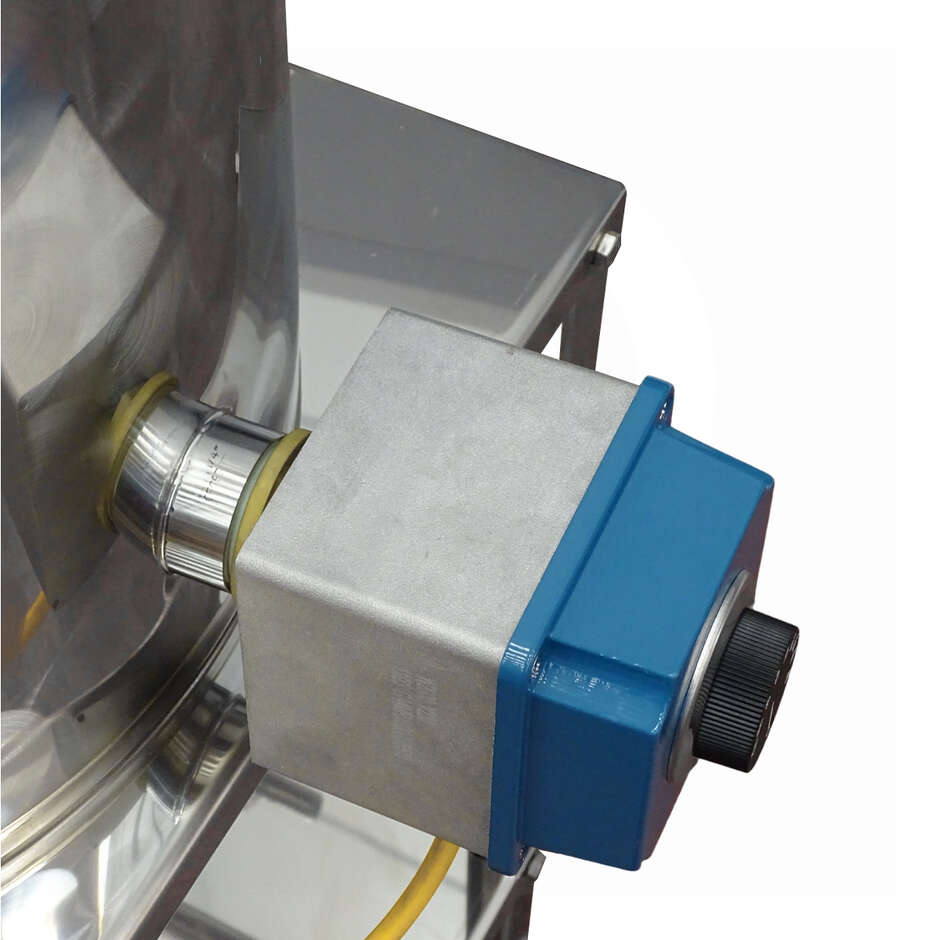

The resistance is in stainless steel with a probe and thermostat:

- Complete with regulation thermostat from 0 ° C to 120 ° C

- 1" ¼ male connection

- Absorption 2 Kw